In talking with customers every day, I’ve come to realize there is some confusion out there as to the various safety aspects of a confined space and the rights and responsibilities of those who work in or around them. Over the coming weeks, we’re going to do a series of summary posts in an effort to help clarify this topic a little.

In talking with customers every day, I’ve come to realize there is some confusion out there as to the various safety aspects of a confined space and the rights and responsibilities of those who work in or around them. Over the coming weeks, we’re going to do a series of summary posts in an effort to help clarify this topic a little.

In this post, we’ll talk about the 2 main types of confined spaces – permit and non-permit required – and their differences. But before we talk about that, let’s first establish what a confined space is as it pertains to worker safety, shall we?

OSHA Confined Space Definition

According to OSHA a confined space is a space that meets these criteria: 1) being large enough for an employee to enter and perform work; 2) has limited or restricted means for entry or exit; and 3) is not designed for continuous occupancy. This describes many kinds of areas a worker can come in contact with on a daily basis whether on a construction site or elsewhere. And it also illustrates what would be considered a non-permit required confined space.

What is a Permit Required Confined Space?

Now, a permit-required confined space will contain all of the above, plus one or more of the following:

- a substance that has the ability to engulf or asphyxiate the entrant

- a potentially hazardous atmosphere

- spaces with inwardly converging walls within the space or a floor that slopes downward, tapering to a small cross-section

- contains any other serious safety or health hazard

Once a confined space has been identified as having any one of the above four potential hazards, an employer should identify it as such via either safety signs or another effective means of communication. Any time an employer has workers that will be entering confined spaces, there needs to be a written program developed that outlines and instructs on the proper safety procedures for working around and occupancy of these confined spaces.

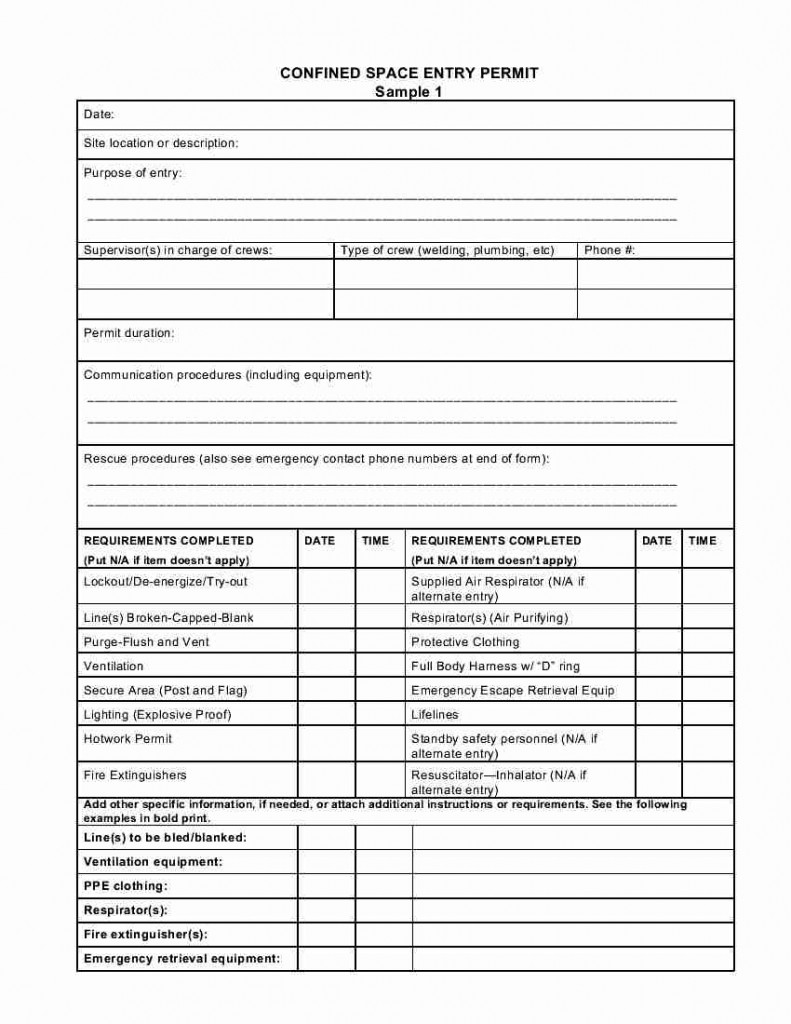

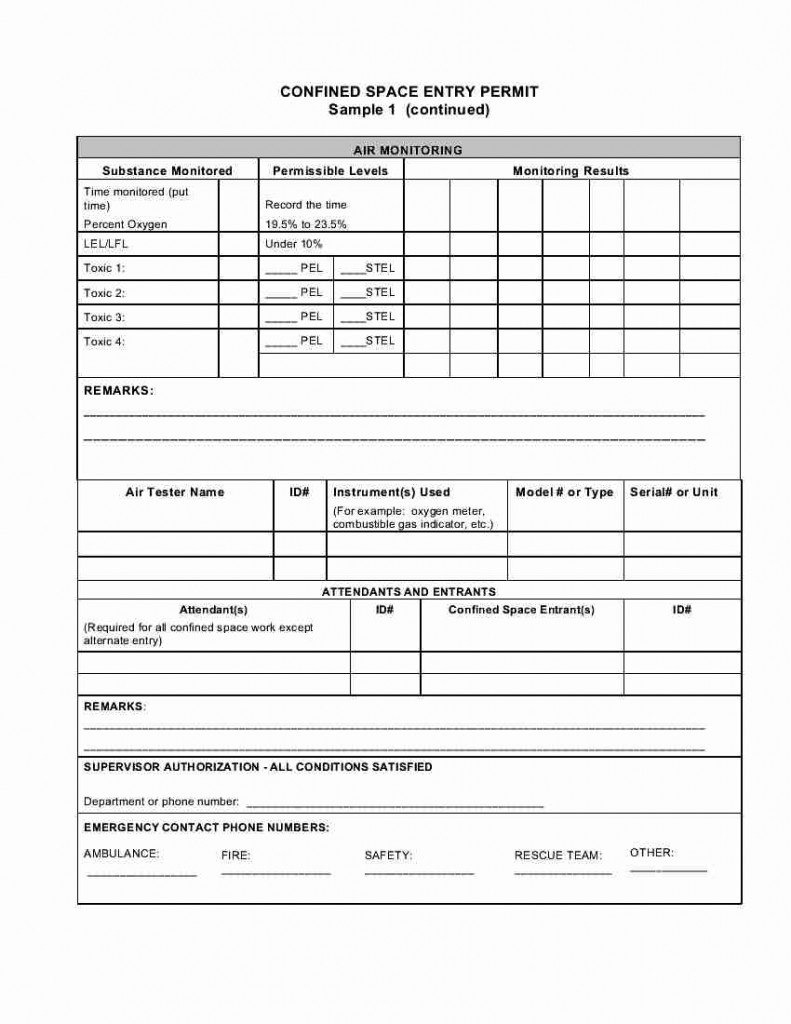

One such important procedure is drafting the actual permit for the permit required confined space. This is called the entry permit and is defined by OSHA as:

the written or printed document that is provided by the employer to allow and control entry into a permit space and that contains the necessary information as required in paragraph (f) of this standard’s section.

I can hear you now…just dying to find out what is in paragraph f! Well, don’t get too excited, because OSHA lists 14 required pieces of information that need to be on a confined space entry permit. And in the spirit of resourcefulness, I’ll list each one here in the following section, but thought it might also be helpful to show an example of a typical confined spaces entry permit, with all of the correct information, so I’ve included that after the list. Without further ado, the following information is what OSHA wants to see on an entry permit for confined spaces:

a confined space entry permit. And in the spirit of resourcefulness, I’ll list each one here in the following section, but thought it might also be helpful to show an example of a typical confined spaces entry permit, with all of the correct information, so I’ve included that after the list. Without further ado, the following information is what OSHA wants to see on an entry permit for confined spaces:

(1) The confined spaces to be entered;

(2) The purpose of entry;

(3) The date and authorized duration of the permit;

(4) The authorized entrants within the permit space, by name or some other means that will enable the attendant to determine quickly and accurately, for the duration of the permit, which authorized entrants are inside the permit space;

(5) Names of attendants;

(6) Supervisor’s name, with a space for the signature or initials of the supervisor who originally authorized entry;

(7) The hazards of the confined spaces to be entered;

(8) The measures used to isolate the permit space and to eliminate or control any occupational hazards before enter (i.e. purging, flushing, or ventilating the confined space as well as lockout and tagging of equipment);

(9) Acceptable entry conditions;

(10) The results of any initial and periodic tests performed, accompanied by the names or initials of the testers and by an indication of when the tests were performed;

(11) The rescue and emergency services that can be called on and the means (such as the equipment to use and the numbers to call) for reaching those services;

(12) The communication procedures used by authorized entrants and attendants to maintain contact during the entry;

(13) Equipment, such as personal protective equipment, testing equipment, communications equipment, alarm systems, and rescue equipment, to be used in the confined spaces;

(14) Any other information whose inclusion is necessary, given the circumstances of the particular confined space, in order to ensure employee safety; and any additional permits, such as for hot work, that have been issued to authorize work in the permit space.

So as you can see, the differences between the two types of confined spaces is large enough to require the distinction, and important to know. It’s not limited to simple identification of where to enter or exit. Confined Space work is one of the leading causes for occupational fatalities in the U.S. A big part of that comes from workers not being properly prepared, or even having knowledge of, the potential hazards that can be lurking within a space they need to enter and perform work and exit.

Knowing the difference between a permit and non-permit required space will help prepare you for those working hazards by knowing when proper safeguarding measures need to be taken. If you’d like to know more about this topic, and be properly certified in this area, we offer a Supervisor and a Confined Space Training Course.