Accidental releases of industrial products lead to fires, explosions, and death. Famous ones make the news. But in an average year, there are 34,000 hazmat incidents in the US, which makes this a very prevalent hazard across a variety of industries and job sites. More than half are spills of fewer than 10 gallons. The wrong handling of even a few gallons can lead to disaster.

Accidental releases of industrial products lead to fires, explosions, and death. Famous ones make the news. But in an average year, there are 34,000 hazmat incidents in the US, which makes this a very prevalent hazard across a variety of industries and job sites. More than half are spills of fewer than 10 gallons. The wrong handling of even a few gallons can lead to disaster.

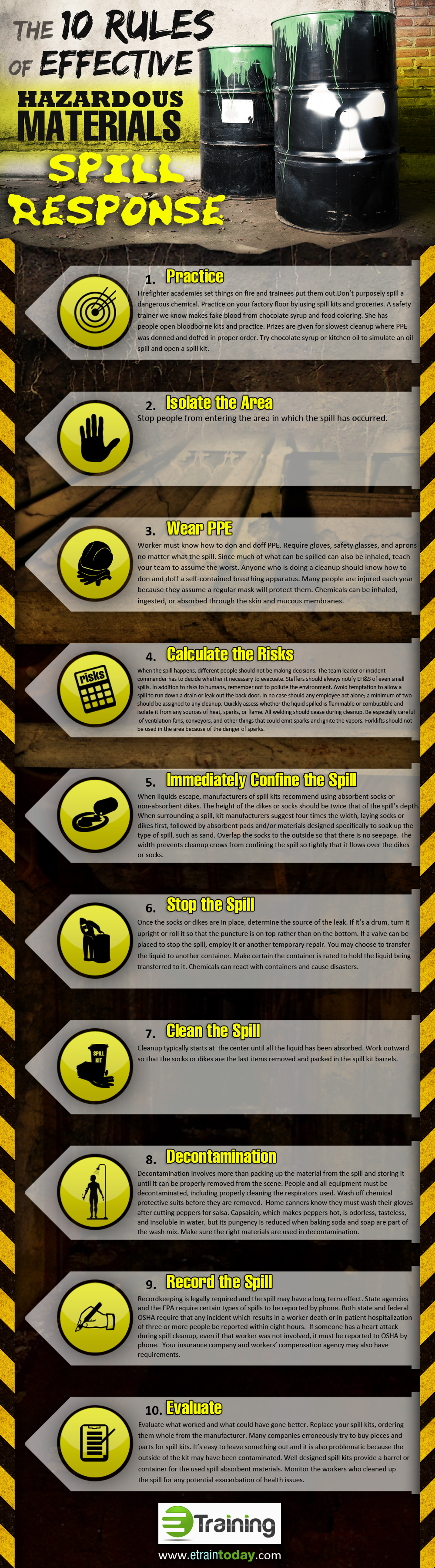

We’ve put together a 10 point infographic list at the bottom of this post for you to download, print, and use at your location! Proper in-depth HAZWOPER training program is a very important part of preparing for an accident, but here are the main considerations – the 10 rules for effective hazardous materials handling response, if you will – to help prepare for and respond to a HazMat spill:

- Practice

- Isolate the Area

- Wear PPE

- Calculate the Risks

- Immediately Confine the Spill

- Stop the Spill

- Clean the Spill

- Decontamination

- Record the Spill

- Evaluate

Practice

Firefighter academies set things on fire and trainees put them out. Don’t purposely spill a dangerous chemical. Practice on your factory floor by using spill kits and groceries. A safety trainer we know makes fake blood from chocolate syrup and food coloring. She has people open bloodborne kits and practice. Prizes are given for slowest cleanup where PPE was donned and doffed in proper order. Try chocolate syrup or kitchen oil to simulate an oil spill and open a spill kit.

Isolate the Area

Stop people from entering the area in which the spill has occurred.

Wear PPE

Wear PPE

Workers must know how to don and doff PPE. Require gloves, safety glasses, and aprons no matter what the spill. Since much of what can be spilled can also be inhaled, teach your team to assume the worst. Anyone who is doing a cleanup should know how to don and doff a self-contained breathing apparatus. Many people are injured each year because they assume a regular mask will protect them. Chemicals can be inhaled, ingested, or absorbed through the skin and mucous membranes.

Calculate the Risks

When the spill happens, different people should not be making decisions. The team leader or incident commander has to decide whether it is necessary to evacuate. Staffers should always notify EH&S of even small spills. In addition to risks to humans, remember not to pollute the environment. Avoid temptation to allow a spill to run down a drain or leak out the back door. In no case should any employee act alone; a minimum of two should be assigned to any cleanup. Quickly assess whether the liquid spilled is flammable or combustible and isolate it from any sources of heat, sparks, or flame. All welding should cease during cleanup. Be especially careful of ventilation fans, conveyors, and other things that could emit sparks and ignite the vapors. Forklifts should not be used in the area because of the danger of sparks.

Immediately Confine the Spill

When liquids escape, manufacturers of spill kits recommend using absorbent socks or non-absorbent dikes. The height of the dikes or socks should be twice that of the spill’s depth. When surrounding a spill, kit manufacturers suggest four times the width, laying socks or dikes first, followed by absorbent pads and/or materials designed specifically to soak up the type of spill, such as sand. Overlap the socks to the outside so that there is no seepage. The width prevents cleanup crews from confining the spill so tightly that it flows over the dikes or socks.

Stop the Spill

Once the socks or dikes are in place, determine the source of the leak. If it’s a drum, turn it upright or roll it so that a puncture is on top rather than on the bottom. If a valve can be placed to stop the spill, employ it or another temporary repair. You may choose to transfer the liquid to another container. Make certain the container is rated to hold the liquid being transferred to it. Chemicals can react with containers and cause disasters.

Clean the Spill

Cleanup typically starts at the center after all liquid has been absorbed. Work outward so that the socks or dikes are the last items removed and packed in the spill kit barrels.

Decontamination

Decontamination involves more than packing up the material from the spill and storing it until it can be properly removed from the scene. People and all equipment must be decontaminated, including properly cleaning the respirators used. Wash off chemical protective suits before they are removed. Home canners know they must wash their gloves after cutting peppers for salsa. Capsaicin, which makes peppers hot, is odorless, tasteless, and insoluble in water, but its pungency is reduced when baking soda and soap are part of the wash mix. Make sure the right materials are used in decontamination.

Record the Spill

Record keeping is legally required and the spill may have a long term effect. State agencies and the EPA require certain types of spills to be reported by phone. Both state and federal OSHA require that any incident which results in a worker death or in-patient hospitalization of three or more people be reported within eight hours. If someone has a heart attack during spill cleanup, even if that worker was not involved, it must be reported to OSHA by phone. Your insurance company and workers’ compensation agency may also have requirements.

Evaluate

Evaluate what worked and what didn’t. Replace your spill kits, ordering them whole from the manufacturer. Many companies erroneously try to buy pieces and parts for spill kits. It’s easy to leave something out and it is also problematic because the outside of the kit may have been contaminated. Well designed spill kits provide a barrel or container for the used spill absorbent materials. Monitor the workers who cleaned up the spill for any potential exacerbation of health issues.

Responsible organizations improve employee education and knowledge of the potential hazards involved in their every day work. Look to eTraining for a variety of courses including our 40 hr HAZWOPER, to meet your needs so that you avoid making the news.