Most safety programs are busy being busy. Safety compliance doesn’t equal worker protection. Organizations invest heavily in toolbox talks, JSAs, and audits, while construction still accounts for 19% of all US workplace fatalities, over 1,000 deaths annually.

The disconnect reveals a fundamental problem: we’ve confused activities about safety with the actual work of keeping people safe (physical controls, worker expertise, and systems that support frontline decisions).

Safety Work vs. The Safety of Work

Safety Work = Everything you do about safety: Toolbox talks – JSAs and Take-5s – Audit checklists – Training certificates – Safety meetings

The Safety of Work = How work actually gets done safely: Physical controls that eliminate hazards – Worker expertise and judgment – Systems that support frontline decisions

OSHA has 1,802 inspectors for 11.8 million workplaces covering 161 million workers. That’s one inspector per 84,937 workers. The current OSHA budget amounts to $3.92 per worker.

The FY 2026 budget proposes cutting OSHA funding by 7.9%, from $632.3 million to $582.4 million. Reduction in funding could lead to an even lower number of inspectors and a further decrease in inspection capacity.

Paperwork keeps growing, yet the gap between what safety departments do and what actually keeps workers safe gets wider every year.

Four Signs You’re Running Safety Theater

1. You measure compliance, not capacity

Your dashboards track training completion rates and JSA signatures. But ask yourself: what do your workers do when conditions don’t match the procedure?

New York construction companies operated comprehensive safety programs in 2023. They still saw 74 deaths, up 48% from 2022. 74% of fatal incidents had preventable safety violations. Compliance looked perfect on paper.

2. Training equals checking boxes

When training becomes about completion rates instead of comprehension, workers pass tests but don’t know what to do when things go sideways. The gap between documented compliance and actual competence grows invisibly until someone gets hurt.

Effective safety training builds competence through scenario-based learning, not just certificate generation.

3. Procedures exist for liability, not protection

Golden rules about hard hats in parking lots. No systematic fall protection plan for roof work. Workers notice the gap. They tune out everything.

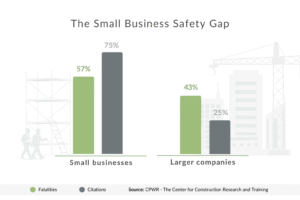

4. Small businesses drown in paperwork

Companies with 1-10 workers account for 57% of fatal construction injuries yet receive 75% of OSHA citations. These small crews often have the most experienced workers on site. They lack systems to support good judgment because they’re buried in compliance documentation they can’t afford to staff.

The Decluttering Framework

Step 1: Kill the theater

List every safety activity your team runs in a month. For each one, ask whether it reduces physical risk or just demonstrates compliance.

If it only demonstrates compliance, dig deeper: to whom, and why? Anything that exists primarily for external auditors deserves hard scrutiny.

Step 2: Shift your metrics

Stop measuring training completion rates, JSA signature counts, and audit scores. These tell you how busy your safety program is. They don’t tell you if workers are safer.

Start measuring near-miss reporting rates. Higher is better because it means workers trust you enough to speak up. Track time between hazard identification and physical fix. Measure worker involvement in hazard assessment and frontline suggestions actually implemented.

Step 3: Engineer first, administrate last

For every new safety procedure, ask whether you could engineer this hazard out instead.

Can’t eliminate it? Guard it. Can’t guard it? Redesign the work process. Can’t redesign? Then write the procedure.

Administrative controls (training, procedures, PPE) fail when workers are tired, rushed, or facing production pressure. Engineering controls work regardless.

Step 4: Empower frontline expertise

Your experienced workers are your best safety resource. But empowerment without authority is insulting.

Give them safety committees with real decision power. Stop-work authority without retaliation. Direct input on hazard solutions. And when they identify problems, fix them.

Empty empowerment programs backfire worse than no program at all.

What This Means for Training

Training bridges safety work and safety outcomes when done right. Checkbox training (boring slides, minimal engagement) proves compliance. It doesn’t build competence. Workers click through to get back to work.

Competence-based training works differently. It’s engaging, scenario-based, and mobile-accessible. Content mirrors real jobsite conditions. It respects workers’ time and intelligence. Completion rates hit 80% or higher because workers actually want to finish.

If your training completion rate sits below 70%, you’re not training your workforce. You’re documenting their non-compliance while calling it a program.

Your Next Move

Pick one critical risk area. Ask your crew what gets in the way of doing it safely. Then fix the system problem, not the worker.

Safety culture comes from physical controls that eliminate hazards, workers empowered to solve problems, and training that builds real competence.

Want to See What “Human-focused training” Looks Like?

eTraining’s OSHA-aligned courses are built for engagement and retention, not checkbox compliance. Through applied scenarios, realistic hazards, and interactive knowledge checks, eTraining helps workers practice decision-making in situations theyʼre likely to face on the job. Learn more →

References: Bureau of Labor Statistics. (2024), U.S. Department of Labor, OSHA. (2024), AFL-CIO. (2025), CPWR – The Center for Construction Research and Training. (2024), Provan, D.J., Dekker, S.W.A., & Rae, A.J. (2018), Dekker, New York Committee for Occupational Safety and Health (NYCOSH). (2025)