Working on a construction site or in an industrial setting means dealing with risks every day. Whether it’s a slip, a deep cut, or a serious emergency, knowing how to react fast can make a huge difference. That’s why first aid training isn’t just another box to check—it’s a key part of keeping yourself and your crew safe.

Why First Aid Training Matters

Job sites are packed with hazards: power tools, heavy equipment, high places, and dangerous chemicals. Even if everyone follows safety rules, accidents can still happen. According to Occupational Safety and Health Administration (OSHA)’s regulations under 29 CFR 1926.50, employers are required to ensure that “medical personnel for advice and consultation” are available and that “provisions shall be made prior to commencement of the project for prompt medical attention in case of serious injury.”

If there is not a clinic, hospital, or physician “reasonably accessible in terms of time and distance”—typically interpreted by OSHA as about 3–4 minutes in high-risk environments—then a person with a valid first‐aid certificate must be available on site.

When workers know first aid, they can act quickly in an emergency, preventing minor injuries from getting worse—and even saving lives. For example: in cardiac arrests, studies outside of construction show that early CPR and AED use raise survival rates substantially (from ~5–7% to ~50–60%) when applied quickly.

So, beyond compliance, first aid training is about response time, preparedness, and reducing long-term consequences from injuries.

Must-Know First Aid Skills for Workers

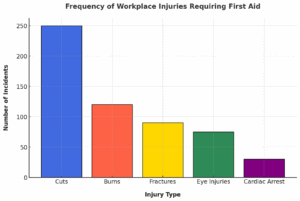

Every worker should have a basic understanding of first aid, especially for common job site injuries. Here are the key skills that should be part of training for construction and industrial workers:

- CPR (Cardiopulmonary Resuscitation)

If a coworker’s heart stops or they collapse, CPR can keep them alive until professional help arrives. As noted above, the window for effective action is very small—making training in CPR (and ideally AED use) a critical piece of the safety puzzle.

- Wound Care

Cuts, lacerations, even amputations happen in industrial settings. Properly cleaning and bandaging a wound helps prevent infection, reduces bleeding, and ensures better recovery. Workers should learn how to inspect wound depth, control bleeding using direct pressure, and when to call for advanced medical attention.

- Fracture and Sprain Management

A broken bone or a badly twisted ankle can turn a site incident into a major medical event. Knowing how to immobilize the injured limb, apply a temporary splint, and safely transfer the worker can prevent further damage, reduce pain, and avoid complications.

- Burn Treatment

Burns can come from fire, chemicals, or electricity; each type needs a different response. Workers should know how to cool thermal burns (e.g., with water), how to flush chemical burns, and how to assess severity. Immediate first aid can affect outcomes, especially with serious burns.

- Eye and Face Injury Response

If debris, chemicals, or projectiles hit the eyes or face, every second matters. Workers must know where eye-wash stations or flush units are located, how to hold their eyes open during flushing, and when to seek emergency care. OSHA’s construction standard 1926.50(g) specifically states that when the eyes or body may be exposed to injurious corrosive materials, “suitable facilities for quick drenching or flushing … shall be provided.”

Additional Skills Worth Considering

- Recognizing signs of heat exhaustion, hypothermia, or cold stress (especially in outdoor settings)

- Recognizing and responding to chemical exposure or inhalation incidents

- Basic airway management, while waiting for EMS

- Basic shock recognition and response (keeping the injured person calm, controlled, and ready for transport)

What Every Job Site First Aid Kit Needs

A solid first aid kit isn’t just nice to have—it’s required. Under 29 CFR 1926.50(d), OSHA mandates that first aid supplies be easily accessible, kept in a weatherproof container, and checked at least weekly on each job.

Essential First Aid Kit Items

Here’s a checklist of items that should appear in a jobsite first aid kit (based on OSHA’s Appendix A to § 1926.50 and ANSI/ISEA Z308.1 guidelines):

- Adhesive bandages (various sizes)

- Gauze pads (4″×4″ and a few 8″×10″)

- Roller bandages (e.g., 2 in wide)

- Triangular bandages (for slings or immobilization)

- Sterile wound-cleaning towelettes or antiseptic wipes

- Scissors and tweezers

- Adhesive tape

- Non-latex gloves (to prevent contamination and protect responders)

- Eye-wash solution or bottle (especially where chemical exposure exists)

- Burn dressings or gel pads

- CPR mask or barrier device

- Splint materials (rigid or inflatable) or items to immobilize limbs

- Emergency instruction card (with site-specific numbers and procedure)

- Blanket or space blanket (for shock, or cold weather)

- Optional but recommended: AED (automated external defibrillator) on site or available nearby

Inspection & Maintenance

- The container must be weatherproof (especially for outdoor or mobile sites).

- The kit should be inspected before each job and weekly while at the job site to ensure used items are replaced and not expired.

- Log inspections and restocks, keep records of when items are used or expired, and update per hazards on site (for example if working with corrosives, eyewash must appear).

Regulatory Requirements: What OSHA Actually Says

You’ll want to be aware of the specific legal requirements, so your site is compliant:

- Under 29 CFR 1926.50(a): “The employer shall insure the availability of medical personnel for advice and consultation on matters of occupational health.”

- Under 1926.50(b): “Provisions shall be made … for prompt medical attention in case of serious injury.”

- Under 1926.50(c): “In the absence of an infirmary, clinic, hospital, or physician … a person who has a valid certificate in first-aid training … shall be available at the worksite to render first aid.”

- Under 1926.50(d)(1)-(2): First aid supplies must be easily accessible; containers must be weatherproof with sealed items; checked weekly.

- Under 1926.50(e): Proper equipment for prompt transportation or communication to ambulance/physicians must be provided.

- Under 1926.50(f): If 911 is unavailable, phone numbers must be posted; if 911 is available, means of communication must work and site location must be posted if caller location not automatically transmitted.

- Under 1926.50(g): Where eyes or body may be exposed to injurious corrosives, suitable drenching/flushing facilities must be provided.

These regulations underscore that first aid isn’t optional, it’s a required element of job-site health and safety. Companies that fail to provide training, supplies, or timely emergency access may be cited and could face serious consequences.

Training: A Smart Investment in Safety

A well-trained crew is a safer crew. First aid training gives workers the confidence to handle emergencies, reducing injury severity and potentially saving lives. It also helps eliminate the hesitation that sometimes kicks in when accidents happen—trained responders act faster.

Key elements of effective training:

- Certified first aid + CPR (and ideally AED) for designated responders

- Tailored training that matches job-site hazards (e.g., chemical burns, falls, heat stress)

- Regular refreshers (often every 2–3 years for first aid; annually for CPR/AED)

- Site-specific orientation: where kits are located, how to call EMS, site layout, hazard identification

- Scenario-based drills: Simulating slips, lacerations, fractures, burns, chemical exposure helps workers practice responses

Investing in training shows workers that safety is serious and valued—this can boost morale, reduce turnover, and build a culture of safety that complements the gear and procedures you already have.

Real-World Scenario: Responding When It Counts

At a mid-sized industrial plant, a welding contractor was working overhead when a small piece of molten metal splashed onto a coworker’s arm. The injured worker immediately felt the burn and alerted his partner. Because the plant had a designated first‐aid-trained responder on site, the team did the following:

- They retrieved the nearest first aid kit (weatherproof box near the welding bay) and brought it to the injured worker.

- The responder quickly applied a cool burn dressing and measured the area of injury before flushing with clean water.

- Meanwhile another worker dialed the posted emergency number and prepared the transport chair (as the plant was somewhat remote).

- Because the burn was larger than initially thought, the responder recommended hospital treatment and documented the incident in the job hazard log.

Because of that swift response, the injured worker avoided infection, the burn didn’t worsen, and the site avoided a major delay or incident. It also highlighted the importance of keeping the kit stocked (they later discovered their burn gel supply was low) and refreshing workers on where the kit was located.

Final Thoughts

A job site is only as safe as the people working on it—and the preparation behind them. Prioritizing first aid training and keeping first-aid kits fully stocked can create a culture of safety that protects everyone. Being prepared means faster response times, better outcomes, and a safer workplace for all.

Remember: First aid isn’t just compliance, its caring, readiness, and respect for the people who show up to work every day.

To get started on your First-Aid training, take a look at eTraining’s First Aid & CPR Essentials Course. And don’t forget, in person training is required for certification! Consider checking with your local Fire Department or Health Department to find locations and schedule for the hands-on training element.

FAQs

- How often should first aid training be renewed?

It depends on the certification provider, but generally every 2 to 3 years for most first aid courses. CPR/AED certification often needs annual renewal or refresher training. - Are employers required to provide first aid kits on-site?

Yes. Under OSHA’s construction standards (29 CFR 1926.50(d)), first aid supplies must be accessible, stored in a weather-proof container, and inspected weekly. - What should I do if I use something from the first aid kit?

You should immediately report it, replace the item, and ensure the kit is re-stocked and still fully ready. The employer must ensure the kit is checked at least weekly.

References: (OSHA), (ConstructConnect), (ahaclasses.com), (environmentalsafetyupdate.com), (Legal Information Institute), (eCFR)