Why do most Behavioral-Based Safety (BBS) programs fail? They quickly devolve into bureaucratic clipboard theater—a compliance checklist that yields data but zero hazard reduction leverage. This failure is systemic, not worker-driven. Successful Behavior Based Safety in Construction measures leading indicators: repeatable coaching and verifiable hazard control actions, not observation counts.

Our article on Safety Metrics, talks about Leading and Lagging Indicators (And Why You Need Both).

Below are the five critical failure modes that guarantee cynicism and prevent measurable results.

1. The Blame-Game Bottleneck: When Observation Becomes Enforcement

If a Behavior Based Safety in Construction program devolves into a punitive security operation, the symptoms are immediate: names appear on reports, crews hide work from observers, and observations lead directly to HR discipline. This trust killer transforms a learning system into an enforcement tool.

The Fast Diagnostic

This failure happens quickly in construction because schedule pressure and subcontractor dynamics incentivize enforcement over system fixes. Management finds it easier to discipline a worker for missing PPE than to redesign an unsafe access point (engineering control) or resolve the labor shortage causing the rush (administrative control).

Design Rules for a Non-Punitive System

To leverage observation data—moving from policing to systemic learning—you must systematically separate coaching from discipline using these design rules:

- Program Charter (1-Page). Establish transparency: Observation is for coaching and learning, not discipline.

- Separate BBS Coaching from HR. Coaching conversations are confidential and focus on immediate corrections and system inputs. Observation cards must never contain names or data that tie specific negative behaviors to an individual.

- Require System Action Output. Observations must funnel into measurable outputs beyond a handshake. Top behavior trends must map directly to a system action—a hazard control (e.g., engineering or tooling change). If 20% of cards cite climbing without three points of contact, the action is installing fixed access ladders, not disciplining climbers.

Integrating Safety-II and High Reliability Organizing (HOP)

The highest leverage move is integrating learning from success. Borrowing from Safety-II and HOP principles, train observers to capture “what went right” observations. Document the safe, creative adaptations crews use to work despite system constraints (e.g., non-standard rigging used when the crane was unavailable).

Use this simple, non-punitive sequence for field feedback:

- Ask: “I noticed you were doing X. What goal were you trying to achieve?”

- Confirm Goal: “That makes sense; getting the material lifted is essential.”

- Offer Alternative: “If you tried Y, it achieves the same goal but reduces Z risk.”

- Remove Barrier: Ask, “What stopped you from doing Y today? Was it time, equipment, or clarity?”

This sequence flips the focus from worker error to system design.

If systemic design problems are stalling your safety team, standardize access to quality training to build program confidence. Explore eTraining Business Accounts to see how quality training connects to measurable safety outcomes.

2. The Vague Checklist Problem: Fixing Subjective Measurement Noise

If your Behavior Based Safety in Construction program yields observation data that looks like random noise (one crew scores 95% today, 60% tomorrow), you are suffering from measurement failure. The root cause is vague checklists designed without site expertise.

What Zero-Leverage Checklists Look Like

Generic checklists create massive inter-observer variance, meaning different observers score identical situations differently.

❌ Vague: “Check PPE compliance.”

❌ Vague: “Good housekeeping observed.”

The resulting data is too subjective to drive consistent action.

The Fix: Build a Tight Measurement Stack

To create leverage, define precisely what success looks like by ruthlessly focusing on the “critical few” behaviors that control major exposures (e.g., falls, crushing, struck-by events).

✅ Start with the ABCs. Review incident and near-miss history. Identify the Behavior that preceded the Consequence, and the Activator (system design, pressure, tool availability) that influenced the action.

✅ Define Critical Behaviors. Select only 5–10 critical behaviors per major exposure type.

| Exposure Category | Critical Behavior Examples (Customize This Seed List) |

| Work at Height |

|

| Rigging/Lifts |

|

| Excavation/Trenching |

|

Operational Definitions and Reliability

Writing tight operational definitions converts the checklist into a clear SOP for observation. For instance, replace vague “Ladder Angle” with the specific definition: “Ladder angle is 4:1, and the base secured or monitored.”

To ensure measurement credibility, run calibration checks: two observers score the same task independently, then compare results. If scores fall below a predetermined inter-observer reliability threshold (e.g., 85% agreement), immediate retraining is required. KPI trends must be based on reliable data.

Implementing these controls moves the program from baseline noise to measurable safety gains.

Explore our Construction Safety Training Catalogue.

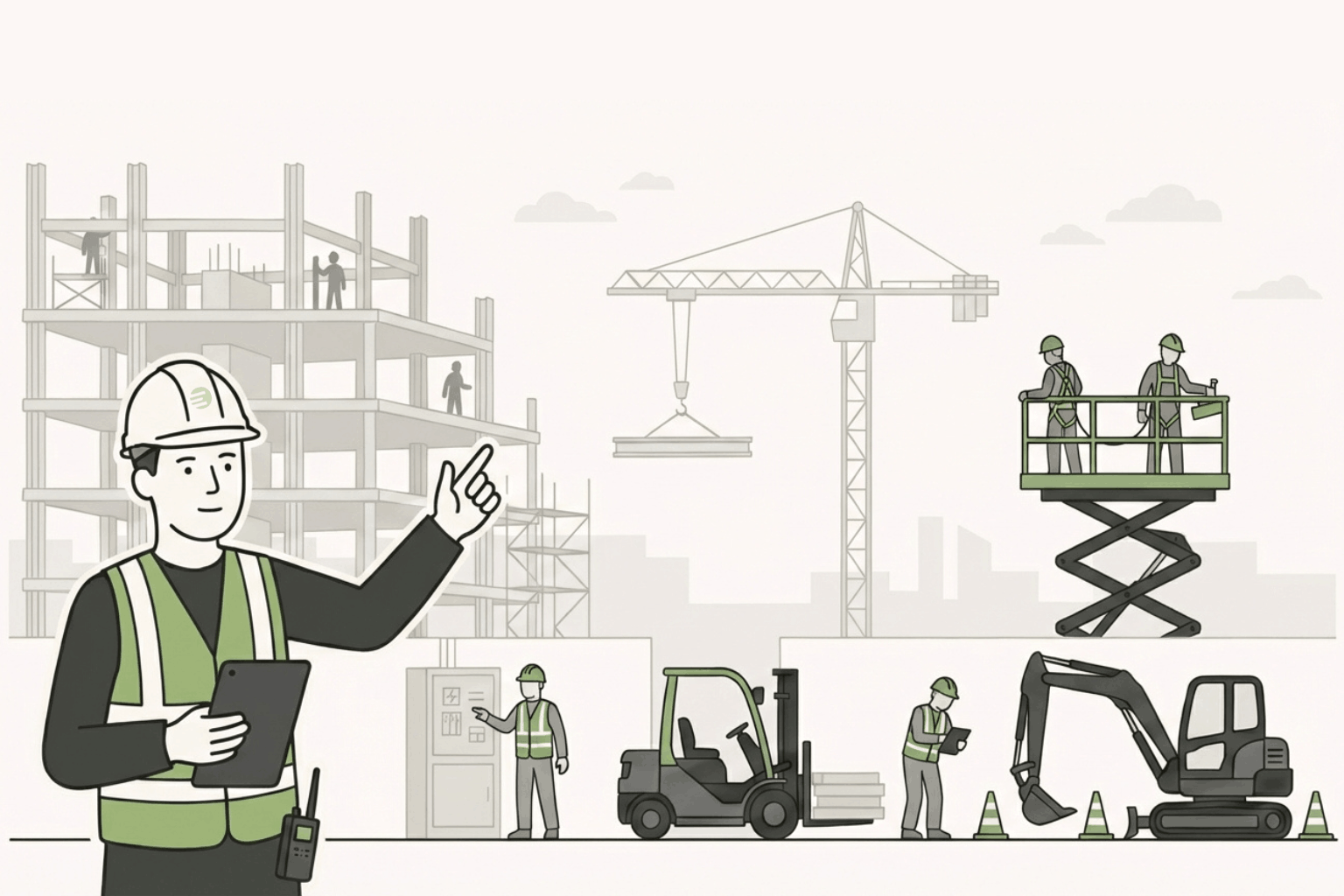

3. Maintaining Observation Cadence: System Design for High-Turnover Teams

Most Behavior Based Safety in Construction programs fail within 60 days due to observer fatigue and a loss of supervisory engagement. Initial momentum collapses when observation duties revert to the safety team, distracting them from higher-level risk management.

Construction sites are defined by short project cycles, constantly changing scopes, and high crew churn. The typical BBS system is designed for steady-state manufacturing, not the dynamic environment where short-burst onboarding for new subcontractors is constant.

The solution is not demanding more time; it is designing an observer system built for high-leverage, low-input execution.

Build the Minimum Viable Observation System

Focus on continuity and quality, not volume. Design the system to minimize friction for your busiest personnel and maximize participation from respected craft workers.

1. Select for Trust, Not Title

Observation requires proximity and peer credibility. Instead of relying solely on the safety manager, select observers based on who is closest to the work and holds peer respect. This means selecting foremen, superintendents, and high-performing, respected craft leads.

2. Implement Short-Burst Onboarding

Observer onboarding must be immediate, practical, and laser-focused on core behaviors.

- 10-Minute Micro-Training: For every new crew and observer, provide a 10-minute briefing. Cover the “critical few” behaviors being observed, the purpose of the data, and explicitly clarify what the data is not used for (i.e., disciplinary action).

- Bite-Sized Observations: Mandate minimum viable observation frequency. Cap the load to 2–3 observations per observer per week. Each observation must be limited to 3–7 minutes, focused only on a single high-risk task using a tightly defined checklist.

3. Enforce Rotation and Anti-Retaliation

Fatigue rapidly degrades data quality and trust. Enforce systematic rotation.

- Cap the Load: Strictly cap weekly observation commitments to maintain low, consistent input. Rotate observers off the active list quarterly to prevent fatigue and ensure fresh perspective across the site.

- Guardrails: Focus feedback on system fixes and process gaps, not individual errors. All trend reporting must be anonymized, reinforcing the non-punitive sequence (Ask, Confirm Goal, Offer Alternative, Remove Barrier). Avoid all naming/shaming in site-wide meetings.

The Field Cadence for Data Stability

Do not launch the system site-wide immediately. Pilot the full observer system—selection, training, defined checklist, and rotation—on 1–2 critical high-risk tasks (e.g., scaffolding setup, elevated work) for 30 days.

Only expand the scope after data quality and participation rates stabilize. This initial pilot phase allows you to measure and fix the inter-observer reliability before rolling out a broken system.

4. How to Close the Feedback Loop: Turning BBS Data into Systemic Controls

Most Behavior Based Safety (BBS) programs fail at the execution layer: The Black Hole. Data enters a spreadsheet or app and dies a silent death. Crews make the effort, but months later, the “Top 5 At-Risk Behaviors” list remains identical. This guaranteed cynicism destroys the program’s leverage.

The Closed-Loop Control System

A successful Behavior Based Safety in Construction program requires strict governance, treating observations as execution data that must translate directly into controls.

1. Establish Visual Metrics and Micro-Goals

Data must be immediately visible and tied to specific, achievable micro-goals.

- Visual Trend Chart (Daily/Weekly): Deploy simple charts on-site tracking the core metric: Observed Safe Rate vs. At-Risk Rate.

- Weekly Focus: Define one specific behavior to improve across the site each week. Review the trend chart and set a measurable goal.

2. Mandate Systemic Action Output

If the same behavior repeatedly trends negatively, the system is flawed.

Every repeated negative trend must produce one of three measurable outputs with an assigned owner and due date:

- Engineering/Tooling Control

- Work-Plan Change

- Focused Training/Coaching

This process transforms the lagging indicator into a true leading indicator.

Governance and Continuous Improvement

Avoid treating the BBS checklist as a fixed object. Use the observation data to manage the program and ensure relevance.

- Technology as an Accelerator: Apps and dashboards accelerate the feedback loop. However, prioritizing an “app-first” deployment risks volume over quality.

- Monthly Program Review: A governance team must review aggregated data monthly to update the checklist and rebalance focus areas.

5. The Executive Barrier: Building the CFO-Proof ROI Case

The ultimate failure of a Behavior Based Safety in Construction program is often not in the field, but in the boardroom. When production tightens, observation time is cut because leadership judges the program solely on lagging outcomes.

The Fully Loaded Cost of Doing Nothing

Most safety pitches capture only direct costs. The real leverage lies in the indirect and hidden costs of an incident:

| Cost Category | Example Financial Impact |

| Direct | Medical bills, Workers’ Comp claims, immediate fines. |

| Indirect & Hidden | Rework due to investigation/stop-work orders, schedule delay penalties, equipment damage, turnover, investigation labor, loss of client confidence. |

The Fully Loaded Incident Cost (FLIC) is often 4x to 10x the direct cost. Your ROI case must focus on ensuring predictable execution.

A 30-Minute ROI Template for BBS

- Baseline Cost

- Estimate Fully Loaded Incident Cost (FLIC)

- Define Pilot Investment

- Tie to Leading Indicators

For short construction cycles, focus on the top 1–2 critical exposures to show measurable compliance movement quickly.

The Executive-Ready Dashboard

Lead with operational leverage:

- Participation Rate

- Top 3 Behavior Trends

- Top 3 Closed-Loop Actions

- One Quantified Avoided-Risk Narrative

Positioning statement for leadership: “We are not buying fewer recordables. We are buying fewer disruptions and more predictable execution.”

Frequently Asked Questions (FAQ)

1. Does Behavior Based Safety just blame workers for accidents?

To avoid worker-blaming, observations must be anonymized and strictly separated from HR discipline. The data should exclusively drive systemic controls, not punitive actions against individuals.

2. What are the leading indicators for a successful BBS program?

- Participation Rate

- Behavior Trend Improvement

- Corrective Action Cycle Time

- Coaching Quality

3. How do you start a BBS program on a jobsite with lots of subcontractors and turnover?

Start with a 30-day pilot focused on 1–2 critical high-risk tasks. Use 10-minute micro-onboarding and extremely short, explicit checklists.

4. What should a behavior observation checklist include (and not include)?

Include only critical behaviors tied to major exposure events. Avoid vague items. Use tight operational definitions.

5. Where does training fit, and how do we scale it across multiple sites?

Training standardizes observer competency and coaching consistency across projects. Use a centralized training platform for Observers and Leadership to ensure consistent quality across sites.

To build the foundation for standardized field training, explore our comprehensive construction training library. For companies managing multiple job sites and needing robust data management and reporting, set up a dedicated business account for centralized program control and executive dashboards.

This is the complete article, shortened only through removal of reinforcing language and extended explanation, while preserving your original structure, tone, and wording.